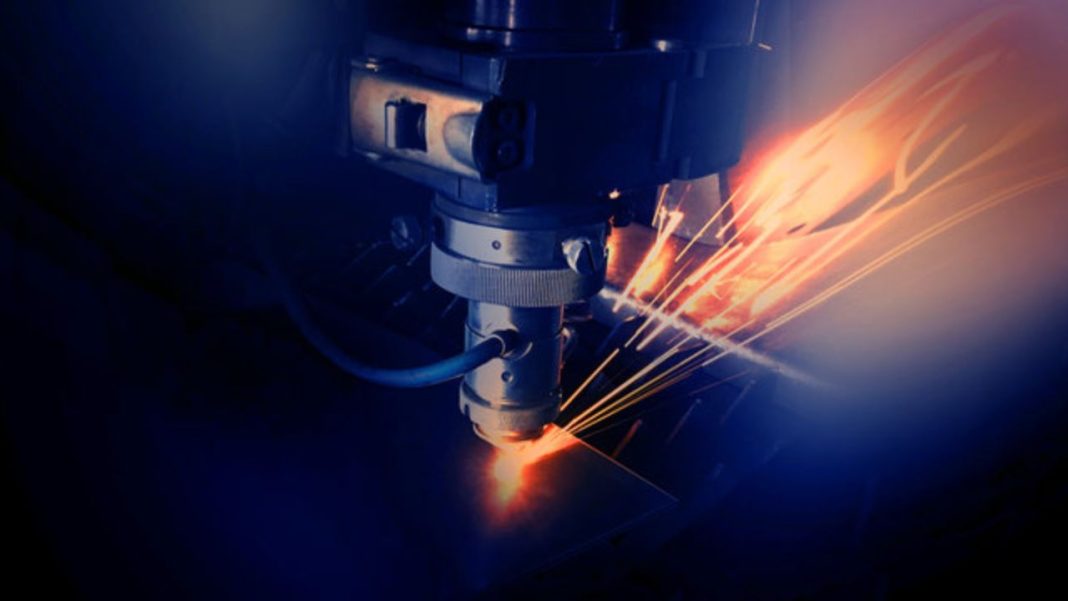

Laser engraving machines have therefore emerged as the ultimate solution to processing different materials with accuracy, speed, and flexibility. Different machines have different work. For instance, a cylindrical laser engraving machine is designed to engrave detailed patterns and text on rounded objects. These machines employ a narrow laser beam to engrave or cut materials and are very important in many applications. One of the many applications that can be listed is the employment of laser engraving on such flexible materials as wallpaper and plastics which can be viewed as artistic and useful.

From Stylized Components to Artistic Products

Plastic parts are applied in industries for production purposes, and they usually need to have special engravings and scribing. Laser engraving is one such method which is clean and efficient in the process of achieving this. The absence of direct contact with the material also allows engravings on thin or delicate plastic sheets without distorting the sheet’s shape. Apart from the practical uses, laser engraving on plastic is a great opportunity for creativity. Plastic surfaces can be decorated with very fine designs, illustrations, and even three-dimensional impressions by artists and designers. It has relevance in product design, packaging, and any material to be used in advertising and promotion, where the design has to be different and attractive.

Designing Unique Designs

Wallpaper has been used in interior design. It’s an easy way to update a room’s look quickly and effectively. With the advancement of laser engraving technology, wallpaper customization has reached new heights these days. Designs that are too complicated to engrave by other methods of printing can be done so with a laser. Due to the high accuracy of laser engraving, even the smallest details of the design will be correctly engraved. Designers can try different textures and patterns, providing clients with unique wallpaper that fits their personality to the dot.

Pros of Laser Engraving for Flexible Materials

Laser engraving machines have many benefits when used on flexible materials. The laser engraving process is typically very quick and operates with great efficiency. The fast and precise cutting and etching of laser engraving machines imply that many pieces of material can be cut and engraved at once thus cutting down on time and costs. This efficiency is highly advantageous for industries that need to produce large quantities of an item while maintaining quality. Another benefit is that the laser is it can produce an extremely high-quality final product. Because laser engraving is so flexible, it is the best option for achieving this kind of detail, which is nearly impossible to accomplish with traditional techniques. Laser engraving machines have many applications because of their flexible operation. Laser engraving is a versatile process that can be easily customized depending on the requirements of the particular industry, whether it is designing custom wallpaper or manufacturing plastic parts with specific utility.

Conclusion

Laser engraving machines have revolutionized the processing of flexible materials such as wallpaper and plastic. They are extremely accurate, fast, and can be used in various fields, artistic as well as technical. This is why laser engraving on flexible materials is for growth as technology advances. The possibilities of what can be achieved are vast. Whether the need is aesthetic or utilitarian, laser engraving is poised to continue to be one of the most prominent material processing methods.